Precision Engineering in the Financial Capital: Why Choose a Brass Item Manufacturer in Mumbai?

In the vast landscape of Indian industry—from automotive and electrical systems to marine and plumbing applications—the integrity of a project often rests on its smallest components. When high conductivity, corrosion resistance, and precision are non-negotiable, brass is the material of choice.

But where you source your components matters just as much as what they are made of.

We, at [Your Company Name], are proud to be a leading Brass Item Manufacturer in Mumbai. We leverage the strategic, industrial, and logistical advantages of India’s commercial capital to deliver not just products, but guarantees of quality and consistency. This comprehensive guide explores why choosing a Mumbai-based brass manufacturer is the smartest decision for your B2B needs.

2. The Mumbai Advantage: Logistics, Talent, and Market Access

Mumbai is more than just a financial hub; it is a global gateway and a powerhouse of industrial excellence. By locating our manufacturing base here, we offer our clients unparalleled advantages:

A. Unbeatable Logistical Supremacy

Mumbai’s infrastructure is arguably the best in India for trade and logistics. We are situated in close proximity to the Jawaharlal Nehru Port Trust (JNPT)—India’s largest container port—and other major shipping facilities.

Faster Raw Material Sourcing: Quick access to imported high-grade brass billets and rods (like $CuZn39Pb3$ for free machining) reduces our lead times and, consequently, yours.

Reduced Export/Import Costs: For international clients, our proximity to major ports significantly cuts down on internal transport costs and turnaround time.

Rapid Domestic Delivery: Seamless connectivity via air, road, and rail ensures that whether you are in Pune, Chennai, or Delhi, your bulk order of brass components reaches you faster and more reliably.

B. Access to Specialized Talent

The industrial belts around Mumbai and its satellite cities (Navi Mumbai, Thane) are rich in highly specialized engineering talent. We employ experienced CNC programmers, master toolmakers, and quality control engineers who understand the demanding requirements of modern precision manufacturing. This specialized knowledge is critical for producing high-tolerance items like brass electrical terminals and custom brass turned components.

C. Direct Market Proximity

Being in the commercial capital places us closer to corporate headquarters, major procurement teams, and decision-makers. This translates into faster communication, quicker clarification on complex designs, and more streamlined project management—a massive advantage over manufacturers located in remote industrial areas.

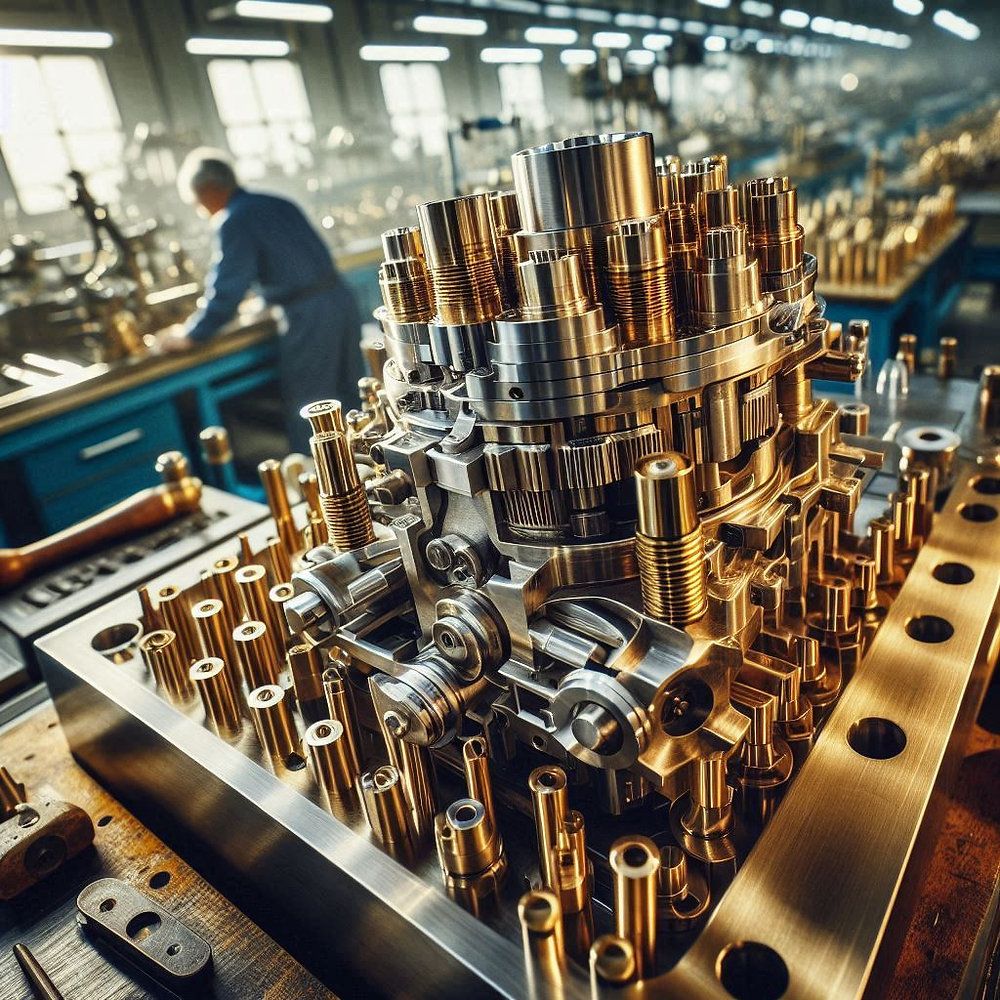

3. The Breadth of Our Brass Item Manufacturing Expertise

As a versatile Brass Item Manufacturer in Mumbai, our product range is designed to serve virtually every demanding industry. We excel in three core categories:

A. High-Precision Brass Electrical Components

The electrical industry demands materials that combine high conductivity with thermal stability. Brass is essential here. We manufacture:

Brass Inserts and Terminals: Used widely in switchgear, circuit boards, and connectors, ensuring zero-defect conductivity.

Neutral Links and Terminal Blocks: Built for safety and reliability in control panels and junction boxes.

Cable Glands and Connectors: Designed to provide robust sealing and termination in harsh industrial environments, particularly effective in coastal areas where corrosion is a major concern.

B. Custom Brass Turned and Machined Parts

Our CNC machining capabilities are at the heart of our operations. We specialize in producing complex geometries with tight dimensional control:

Brass Bushes and Spacers: Crucial for machinery requiring low friction and high durability.

Custom Fittings: For plumbing, pneumatic, and hydraulic systems, often involving intricate threading and multi-axis machining.

OEM Specific Parts: We partner with Original Equipment Manufacturers (OEMs) to reverse-engineer or develop bespoke brass items based on unique application requirements.

C. Brass Fasteners and Hardware

From standard hex nuts and bolts to specialized cold-forged screws, our fasteners offer superior strength and corrosion resistance compared to standard materials, especially useful in marine and chemical processing applications near the coast.

4. The Manufacturing Edge: Quality Control and Technology

A great location is nothing without great quality. Our commitment to being a reliable Brass Item Manufacturer is backed by strict technological and quality control protocols.

A. State-of-the-Art Machining Fleet

Our facility utilizes the latest generation of machinery:

CNC Turning Centers: For high-speed, high-volume production of precision parts with tolerances measured in micrometers.

Automatic and Semi-Automatic Lathes: Used for cost-effective mass production of standard brass components.

Cold-Forging Equipment: For creating high-strength fasteners with superior grain structure.

B. Rigorous Quality Assurance Process

Quality is not an afterthought; it is integrated into every step, from material inspection to final packaging.

Material Inspection: We source only certified brass alloys and conduct Spectrometer Analysis to verify composition against standards like IS, DIN, or ASTM.

In-Process Checks: Operators utilize digital calipers and micrometers, while specialized quality engineers use Go/No-Go Thread Gauges and Profile Projectors to ensure thread integrity and dimensional accuracy.

Batch Traceability: Every finished batch is traceable back to its specific raw material lot and processing parameters, providing total accountability.

This meticulous approach ensures that when you order brass items from our Mumbai facility, you receive components that perform exactly as engineered, every time.

5. Partnership: Beyond the Product

Choosing us means choosing a strategic partnership:

Quick Prototyping: Leveraging the speed of Mumbai’s supply chain, we offer rapid prototyping services to get your custom design approved quickly, shortening your time-to-market.

Scalability: Whether you need a small batch of specialized fittings or a million brass inserts, our facility is engineered for scalable production without compromising precision.

Customer-Centric Focus: We pride ourselves on transparent communication and reliable delivery schedules, allowing your procurement team to manage inventory confidently.

6. Conclusion: Your Reliable Brass Partner in Mumbai

In a demanding industrial world, you need a partner who can deliver uncompromising quality, technical expertise, and logistical reliability. By choosing [Your Company Name], a leading Brass Item Manufacturer in Mumbai, you are investing in the advantages of India’s commercial heartland.

Contact us for any requirement of brass components.

Our team will be happy to assist you.

Mobile: +91-99242 32871