Pneumatic systems are widely used across industries for automation, material handling, manufacturing, and assembly operations. The efficiency and safety of these systems depend heavily on the quality of pneumatic fittings used to connect tubes, hoses, and components. Two of the most common materials for pneumatic fittings are brass and plastic.

Choosing between brass pneumatic fittings and plastic fittings depends on application requirements, operating conditions, and long-term performance expectations. At Gajanan Brass, we manufacture high-quality brass pneumatic fittings designed for reliability and durability. In this blog, we compare brass and plastic pneumatic fittings to help you determine which option is better for your application.

Understanding Brass and Plastic Pneumatic Fittings

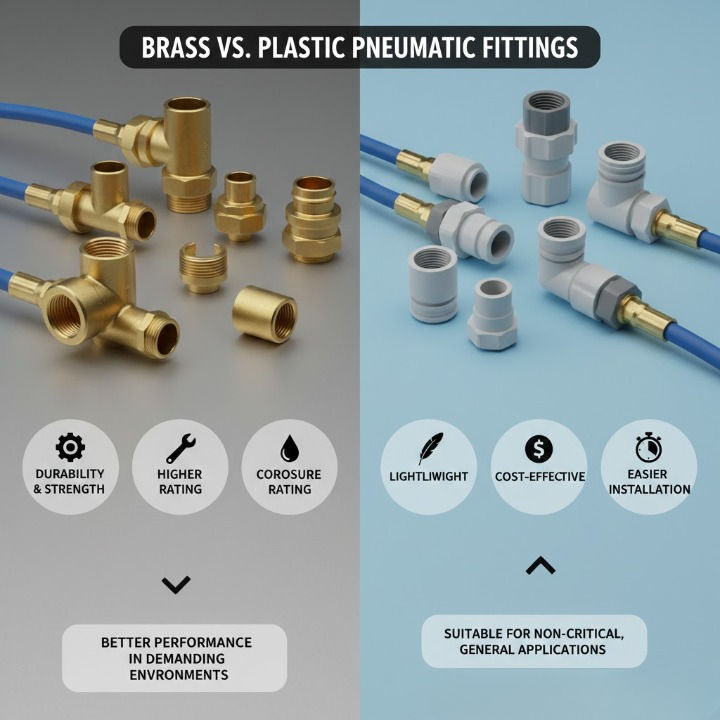

Brass pneumatic fittings are made from a copper–zinc alloy and are known for their strength, corrosion resistance, and precision. They are commonly used in industrial environments where durability and performance are critical.

Plastic pneumatic fittings, typically made from materials such as nylon, polyurethane, or polypropylene, are lightweight and cost-effective. They are often used in low-pressure or non-critical applications.

1. Strength and Pressure Handling

Brass pneumatic fittings offer superior mechanical strength and can withstand higher pressure levels compared to plastic fittings. They are suitable for demanding industrial applications where pressure fluctuations and mechanical stress are common.

Plastic fittings, while adequate for low-pressure systems, may crack or deform under high pressure or sudden pressure spikes.

Verdict: Brass fittings are better for high-pressure and heavy-duty pneumatic systems.

2. Durability and Service Life

Brass fittings are highly durable and resistant to wear, impact, and vibration. They perform reliably in continuous-duty environments and have a long service life.

Plastic fittings are more prone to wear, fatigue, and damage over time, especially in harsh industrial conditions.

Verdict: Brass fittings offer longer service life and greater reliability.

3. Temperature Resistance

Brass pneumatic fittings perform well across a wide temperature range, making them suitable for applications involving heat, compressed air, or temperature fluctuations.

Plastic fittings have limited temperature tolerance and may soften, warp, or become brittle under extreme heat or cold.

Verdict: Brass fittings are more suitable for high-temperature or variable-temperature environments.

4. Corrosion and Chemical Resistance

Brass offers excellent resistance to corrosion caused by moisture, oils, and mild chemicals commonly found in pneumatic systems. This ensures consistent performance over time.

Plastic fittings resist certain chemicals but may degrade when exposed to oils, solvents, or UV radiation.

Verdict: Brass fittings provide better overall resistance in industrial environments.

5. Precision and Leak Prevention

Brass fittings are precision-machined, resulting in accurate threads and tight sealing. This minimizes air leakage, improves system efficiency, and reduces energy loss.

Plastic fittings may lose sealing effectiveness over time due to deformation or wear.

Verdict: Brass fittings ensure more secure and leak-free connections.

6. Weight and Cost Considerations

Plastic pneumatic fittings are lightweight and generally have a lower initial cost, making them suitable for budget-sensitive or temporary applications.

Brass fittings are heavier and may have a higher upfront cost, but their durability and low maintenance requirements result in lower long-term costs.

Verdict: Plastic fittings are cheaper initially; brass fittings are more cost-effective over time.

Plastic fittings may lose sealing effectiveness over time due to deformation or wear.

Verdict: Brass fittings ensure more secure and leak-free connections.

7. Application Suitability

Brass pneumatic fittings are ideal for:

Industrial automation and machinery

Manufacturing plants

High-pressure air systems

Applications requiring long-term reliability

Plastic pneumatic fittings are suitable for:

Low-pressure systems

Lightweight assemblies

Non-critical or temporary installations

Conclusion

When comparing brass pneumatic fittings vs. plastic fittings, the better choice depends on application requirements. Plastic fittings may be sufficient for low-pressure and light-duty systems, but they have limitations in strength, durability, and temperature resistance.

For demanding industrial applications where performance, safety, and longevity are essential, brass pneumatic fittings are the superior choice.

At Gajanan Brass, we manufacture high-quality brass pneumatic fittings that meet international standards and deliver dependable performance across industrial environments. Choosing brass ensures reliability, reduced downtime, and long-term operational efficiency.

Contact us for any requirement of brass components.

Our team will be happy to assist you.

Mobile: +91-99242 32871