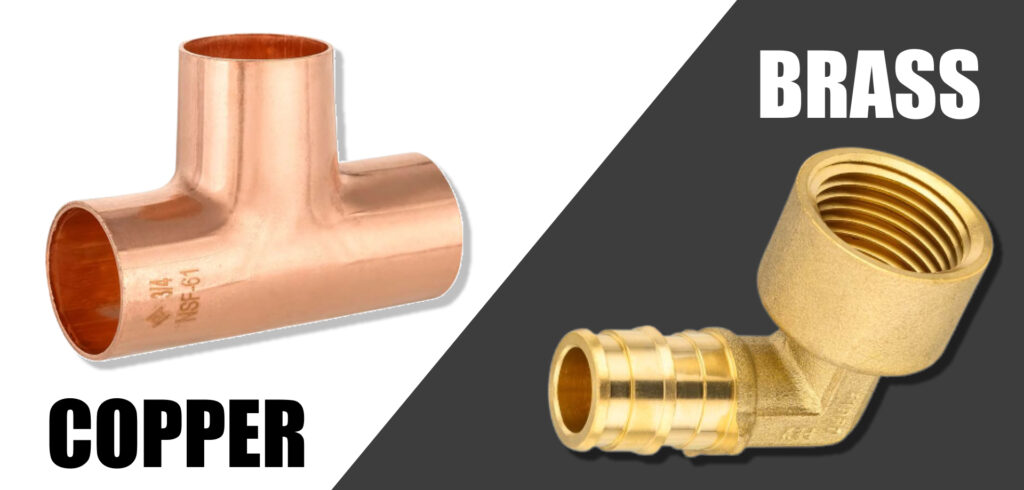

Brass Fittings vs. Copper Fittings: Which is Better for Your Industrial Application?

When designing a piping system—whether for high-pressure hydraulics, residential plumbing, or industrial gas lines—the choice of fittings is critical.1 The debate between Brass Fittings and Copper Fittings is not about which metal is “better” in a vacuum, but rather which is better for your specific application.2

At Gajanan Brass Global, we specialize in precision-engineered brass components, but we believe in helping our clients understand the full metallurgical landscape. In this guide, we break down the chemistry, durability, and cost-efficiency of both materials to help you choose the right fit for your project.

1.Material Composition: Purity vs. Performance

The fundamental difference lies in the “DNA” of the metals.

Copper Fittings: Made from nearly 99.9% pure copper.3 It is a natural element known for its softness, high thermal conductivity, and antimicrobial properties.4

Brass Fittings: An alloy primarily composed of Copper and Zinc.5 By adding zinc, manufacturers create a material that is harder and stronger than pure copper.6 Additional elements like Lead (for machinability) or Tin (for corrosion resistance) are often added to “tune” the brass for specific industrial roles.7

Strength and Pressure Resistance

In industrial environments, mechanical stress is a constant. This is where the alloyed nature of brass provides a distinct advantage.

The Brass Advantage: Because it is an alloy, brass is significantly harder than pure copper.8 It can withstand higher torque during installation and is less likely to deform under heavy mechanical impact.

High-Pressure Systems: For gas lines and high-pressure hydraulic systems, brass is often the preferred choice.9 It resists “creeping” (slow deformation under heat and pressure) better than the softer copper.

Copper’s Limitation: While copper is incredibly durable, it is a “soft” metal. It is prone to denting and can be damaged if subjected to heavy external vibrations or rough handling.

Corrosion Resistance: Knowing Your Environment

Both metals are non-ferrous (they don’t rust like iron), but they react differently to various chemicals.

Copper: The Water Specialist

Copper naturally develops a protective “patina” (the greenish-brown layer) when exposed to oxygen.10 This layer protects the metal from further decay.11 It is exceptionally resistant to corrosion from freshwater, making it a gold standard for potable water lines.12

Brass: The Harsh Environment Survivor

Brass is more resistant to “erosion-corrosion”—the wear caused by high-velocity water or turbulence. However, some types of brass can be susceptible to dezincification (where zinc leaches out) in very acidic or highly chlorinated water.13

Pro Tip: For marine or coastal environments, Naval Brass (which includes Tin) is used because it resists the corrosive power of saltwater far better than pure copper.14

4. Installation and Versatility

The way these fittings are joined to the system is a major factor in labor costs and project timelines.

| Feature | Copper Fittings | Brass Fittings |

| Joining Method | Usually requires Soldering (sweating) | Typically Threaded or Compression |

| Machinability | Difficult to machine intricate threads | Excellent; can be precisely threaded |

| Flexibility | High (can be bent easily) | Moderate (more rigid) |

| Maintenance | Permanent joints; hard to modify | Modular; easy to unscrew and replace |

Why choose Brass for complex systems?

Because brass is highly machinable, it can be manufactured into complex shapes like Tees, Elbows, and Valves with precision-cut threads.15 This allows for a “screw-and-forget” installation that doesn’t require the open flames and specialized skills of soldering copper.16

5. Thermal and Electrical Conductivity

If your project involves heat exchangers or electrical grounding, the choice is clear:

Copper Wins on Conductivity: Pure copper is the second-best conductor of electricity after silver.17 It also has a much higher thermal conductivity than brass (18$223$ vs. 19$64$ BTU/(hrft°F)).20

Brass for Insulation: In some cases, the lower conductivity of brass is an advantage, as it acts as a slight thermal barrier in specific mechanical assemblies.

6. Cost and Economic Value

In 2025, the global metal market remains volatile.

Upfront Cost: Pure copper is generally more expensive than brass.21 Since brass contains a significant amount of zinc (which is cheaper than copper), the raw material cost of brass fittings is often lower.22

Manufacturing Efficiency: Brass is much easier to process through CNC Machining and Forging.23 This manufacturing speed allows companies like Gajanan Brass Global to offer high-quality fittings at more competitive prices than pure copper alternatives.

The Verdict: Which Should You Choose?

Choose Copper Fittings If:

You are running long, continuous water supply lines.

You need maximum thermal conductivity for a heat exchanger.

You are looking for a permanent, soldered connection in a residential build.

Choose Brass Fittings If:

You need threaded connections for valves, gauges, or pumps.24

The application involves high-pressure gas or heavy-duty machinery.

You are working in a marine environment (use Naval/Admiralty Brass).

You need a modular system that can be easily disassembled for maintenance.

Contact us for any requirement of brass components.

Our team will be happy to assist you.

Mobile: +91-99242 32871